Morgan Advanced Materials

New methane storage research has potential to revolutionise energy storage and transportation

With scientific innovation at the core of our business we’re proud to announce that our Performance Carbon Global Labs Manager, Fernando Vallejos Burgos, has co-authored a groundbreaking paper focused on a new approach to methane storage.

Published in the prestigious ‘Nature Energy’ scientific journal, this research focuses on the potential to revolutionise energy storage and transportation by improving safety, efficiency, and accessibility, through a new approach to methane storage.

Reimagining methane storage

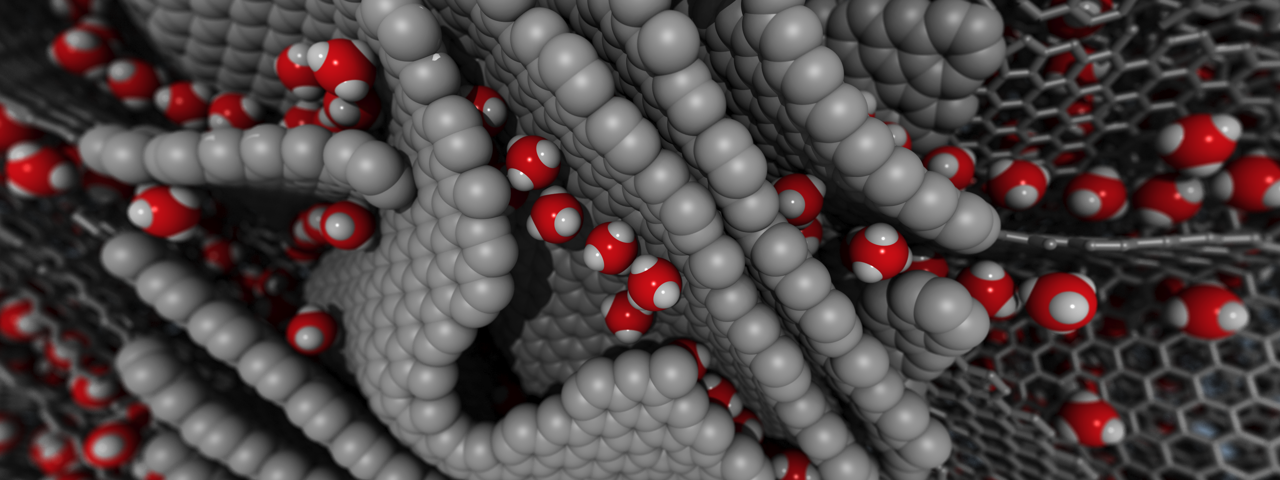

Current methane storage methods rely on high-pressure tanks; an approach that, while effective, comes with safety risks and hefty infrastructure costs. Fernando and his collaborators have developed a novel technique that eliminates this need. By coating porous carbon materials with graphene, methane can be trapped within the material’s pores at ambient temperature and pressure, then released upon gentle heating.

"Our method provides a viable pathway for safe and efficient methane storage. Instead of relying on costly, bulky pressure tanks, this approach significantly enhances safety while reducing costs”

Fernando Vallejos Burgos

A collaborative global effort

Fernando’s journey into this research began with an invitation from a prestigious research team in Japan—a group exploring advanced methods for methane storage. Recognising his expertise in molecular simulations, they sought his assistance in refining the process and optimising efficiency.

Key discoveries and challenges

One of the most surprising findings of the research was that the optimal graphene coating thickness was remarkably thin; just enough to prevent methane from leaking while preserving valuable pore space. The interaction between graphene and the carbon substrate proved more complex than anticipated, requiring significant refinements to simulation models.

Beyond the science itself, publishing the findings was another challenge. The research was submitted to Nature Energy, one of the world’s leading energy journals, and faced an intense two-year peer review process.

It was demanding, with multiple rounds of questioning and requests for additional evidence, but it ultimately pushed us to refine our analysis and strengthen our conclusions.”

Fernando Vallejos Burgos

The Future of Methane Storage

This innovation has the potential for far-reaching applications, from portable methane storage devices to large-scale energy systems for natural gas-powered vehicles. Eliminating high-pressure containment reduces cost and complexity, making methane more accessible and environmentally friendly too.

Learn more about the research in Nature Energy.